Learn how to make Sake

When coming to Japan, many people think that Sake is made from Sake in their country. Actually, you know, Sake is rice wine.

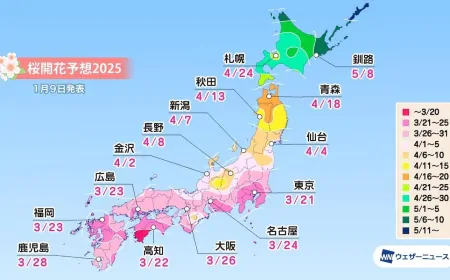

It can be said that Sake's reputation comes from the taste created by this country's strict and delicate winemaking standards. In Japan, one of the best Sake-making areas is Tohoku because this is a land famous for rice with a famous brewery located right in Akita Prefecture.

The entire Sake brewing process is extremely strict, from the selection of rice to the brewing stage, which takes about 6 to 12 weeks in total and is divided into 8 main stages.

1. Rice milling process (Seimai)

Raw rice grains have a lot of impurities that reduce the original aroma and color of rice. Therefore, to form a good quality Sake, one has to mill the rice to get the inner core of only 30-70% of the whole grain of rice. In famous workshops, this standard is only 30 -40%. That said enough to see how strict the standards for making Sake are.

2. Wash, soak and cook rice into rice

The whole process takes up to 1 day to ensure the standard of rice fermentation

3. Fermentation

This is the most difficult and important process in the whole rice cooking process. First, the craftsman will sprinkle the Koji mushrooms on the rice and leave them for 35 to 48 hours. This process will cause the rice to break down and turn into sugar.

Room temperature and humidity are the deciding factors. The whole process will be placed in a special room with the right temperature. The brewers will adjust the temperature continuously every 3 to 4 hours. In particular, the entire room is paved with a type of Japanese wood. In addition to the advanced humidification devices, it is this wood that helps to absorb moisture if the humidity in the room is too high and brings in moisture if it is too low.

4. Moto stage

The artisan will mix Koji, yeast, rice and water. The sugar will be turned into alcohol and fermented for another 2 to 4 weeks.

Do you know? A special feature of the entire Sake brewing process is that all artisans and workers here absolutely do not use fermented foods. They must not eat fermented beans or even yogurt because the yeasts of these foods can come from humans and disrupt the process.

5. Moromi stage

Add Koji, steamed rice and water in a row for 4 days and let it sit for 18 to 32 days to ferment.

6. Wine pressing

After fermentation, the wine is pressed and will be divided into two types: clear white and white base.

7. Filter wine

It's up to the manufacturer whether they want to retain their distinct and natural flavor, with or without this filtration process. The wine will be filtered through the refined powder bar

8. Brewing wine

After that, the wine will be sterilized to kill bacteria and unnecessary elements and then released and incubated. After 8 processes, the wine will be bottled and labeled. For premium wines, bottle labels will be hand-glued to ensure the uniqueness of this national drug.

If you have the opportunity to visit Japan and the Tohoku area, once set foot in the winery to see the process of making wine and enjoy this world famous national drug!

--------------------------

Injavi.com - Visit in Japan

記事に関連する商品